Spinning a Sustainable Future

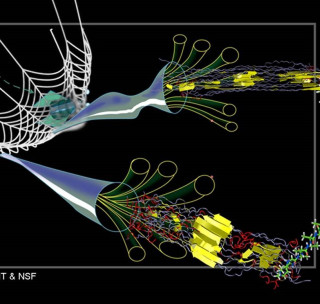

Spider spinning its web. Photo © Schankz/Shutterstock

By Sierra Adler

The silks of the future might not be as soft as you expect. A growing field of biologists and materials engineers are taking hints from spiders, creatures that have spent hundreds of millions of years perfecting silk-making technology, and developing methods to isolate and replicate spider silk proteins for commercial use.

Randy Lewis, a spider silk expert at Utah State University, is a pioneer in the field. Since becoming the first researcher to successfully clone a spider silk protein in 1990, Lewis has continued to prove himself an innovator in the field.

Spiders are cannibalistic and territorial, making it impossible to milk them—rather, silk them—in farms. Instead, researchers can transfer genes from spiders into other organisms, and use those creatures’ natural processes to produce proteins. The primary organisms Lewis uses for this synthetic silk production are bacteria, silkworms, alfalfa, and goats (the proteins turn up in their milk).

Each species of spider produces a unique array of silks, with different qualities of strength and elasticity. With over 40,000 species of spider, that’s makes for myriad silk-technology possibilities. Many organic spider webs are composed of a mix of the silks and glues in that species’ repertoire. By isolating the individual proteins, researchers can use specific proteins for their given mechanical properties, and develop products accordingly.

The range of spider silk products in development are astounding. Lewis’s lab develops coatings, adhesives, fibers, and medical implants. These silk protein adhesives can be up to twenty times stronger than a commercial product like Gorilla glue. However, where Gorilla Glue is rigid, spider silk proteins offer elasticity without forfeiting strength, allowing them to bear greater pressure without breaking. The silk coatings will stick to pretty much anything, and are in development for medical implants, like catheters and micro-sutures.

Lewis is in talks with a number of companies on licensing agreements to develop further commercial uses for his technologies. If the seemingly endless possibilities for creation with this medium aren’t enough of a selling point, Lewis’s lab’s procedures also provide much more sustainable production processes than those for traditional materials. While early silk protein isolation techniques involved harsh and expensive chemicals, Lewis has developed a system to dissolve the proteins in an aqueous solution using standard microwaves. This creates a much easier and more sustainable option.

Lewis is currently working with outdoor retailers in Salt Lake City to develop synthetic spider silk outdoor gear of similar quality to current models. This will offer much lower carbon consequences for production than the current, industry standard, petroleum-produced products.

Alongside Lewis, other spider silk products are beginning to hit the markets. The takeover of spider-silk fibers has already begun, with North Face’s Moon Parka, made from synthetic spider silk, in Japan. It seems only a matter of time until synthetic spider silks are interwoven into society.

Read the latest NHMU science news on our blog.

Sierra Adler is studying science communication at the University of Otago in New Zealand. Sierra is a former intern for the Natural History Museum of Utah, a part of the University of Utah in Salt Lake City. Our mission is to illuminate the natural world and the place of humans within it. In addition to housing outstanding exhibits for the public, NHMU is a research museum. Learn more.